Cabinet Terms to Know ~ Veneers

We'll explain the different types, how we choose them, as well as how we use veneers in the construction of our cabinets.

WHAT ARE VENEERS?

Veneers are a thinly sliced piece of wood. Here's how it works: Premium logs are harvested for their potential to yield this "veneer quality" material. Softwoods undergo this process for cores and building materials while hardwoods like Maple, Birch, Cherry and Walnut, experience the same process for quality face veneers.

These veneers are sliced extremely thin, less than 1/32˝ in thickness to be exact. In this state, they are extremely fragile and handling is of utmost importance. It is the quality of each individual log that will determine the type of cutting process the logs will require. Throughout the process, looking for the best possible yield and closely following demand are factors which remain extremely important.

ARE THERE DIFFERENT TYPES OF VENEERS?

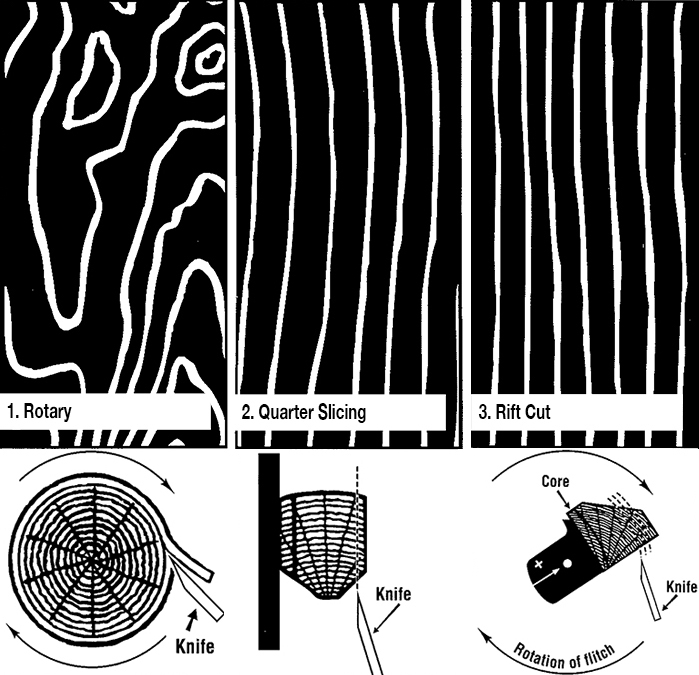

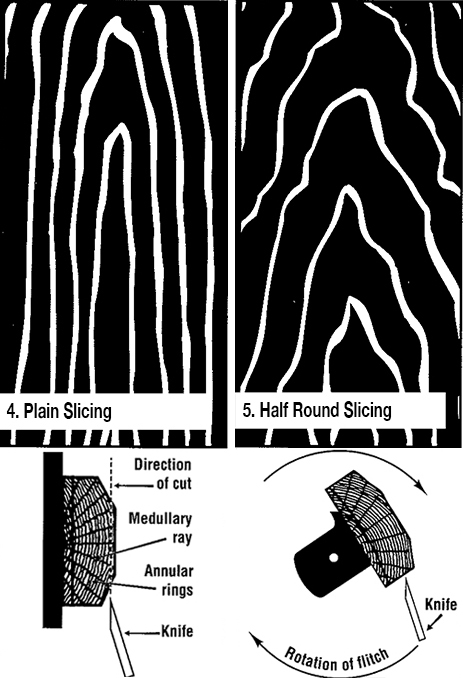

There are 5 primary types of veneer processes:

- Rotary

- Quartered

- Rift Cut

- Plain Sliced

- Half Round Slicing

The most popular of all of these processes is Plain Sliced, because it offers a look that we consider pleasing, and it has a good yield off of the log. Rotary is a faster, less expensive process where the grain pattern is wild and non uniform (which is not very appealing in our industry). Quarter cut and Rift cut are specialty cuts which are produced from various species of Oak. This process yields the unique qualities of fleck grain or straight grain of these beautiful hardwoods. For more information on all these processes, see the below graphics.

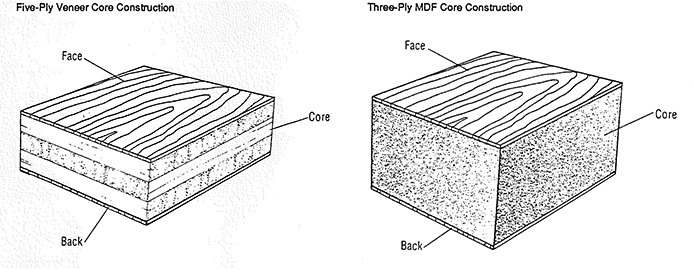

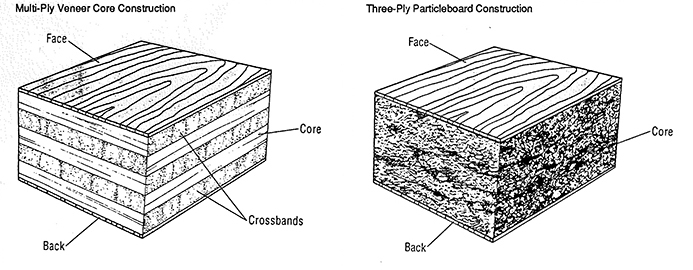

These Veneers are then processed, graded, and applied to a core material (see below images for examples). Next, they are sanded and prepared for manufacturers to purchase. In this form they are commonly referred to as "sheet stock." Plain & Fancy selects only the premium veneers, to ensure the best quality, color and consistency.

How are They Used in the Manufacturing of Your Cabinets?

Sheet stock is used to produce many of the parts that are used in cabinet construction at Plain & Fancy. Dedicated software optimizes the sheets for optimum yield, and jobs are batched and processed through a large industrial panel saw. Here, a scoring blade pre scores the bottom of the panel, in order to eliminate tear out. The large main blade, which is approximately 18˝ in diameter, produces a beautiful smooth cut. All of these cut parts are then labeled and distributed to other areas of the panel processing department, where they are machined as required.

Popular

The Key to Organizing your Kitchen

MAY.4.2023Kitchen organization Is the secret to achieving functionality and flow.

Cabinet Door Styles

JAN.9.2023What's In Store for the next Generation? It's no secret that interior design trends are always changing.

Best White Kitchen Cabinet Colors

SEP.23.2019White is currently a top kitchen color, and for good reason — it promotes a bright, open look that can instantly make even the smallest kitchen appear more spacious.

Latest Videos

50 Years As Family In the Kitchen Cabinet Industry

Plain & Fancy is proud to be a family run business, now in its third generation, for over 50 years.

How to Clean Your Plain & Fancy Cabinets

Learn how to properly clean your Plain & Fancy cabinets.

Fit and Finish

Every inset door and drawer are hand fitted one at a time to ensure a perfect fit.